Quality Management

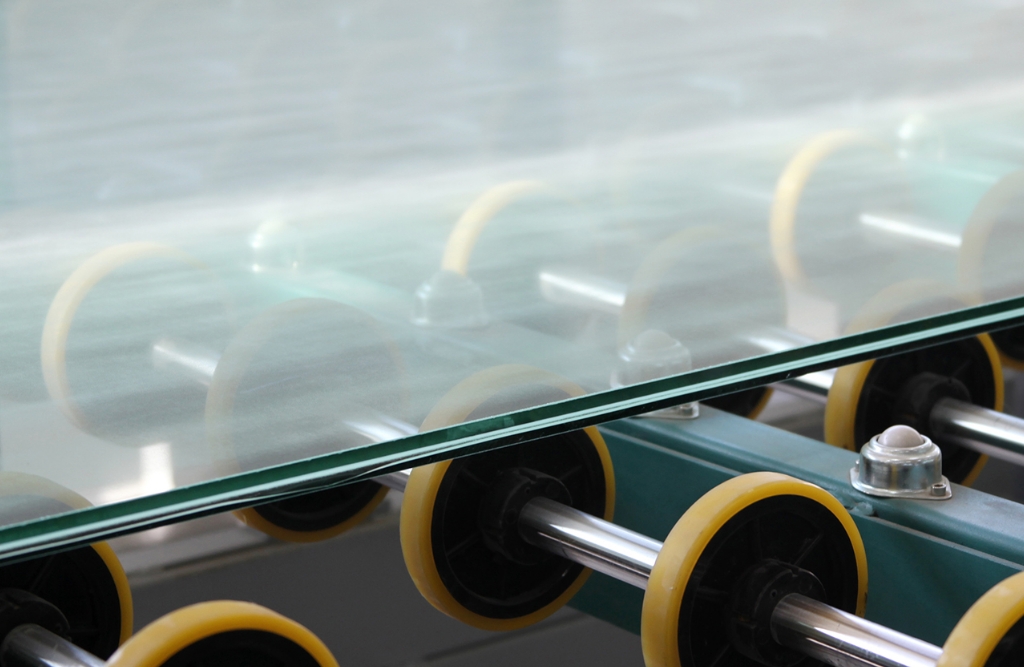

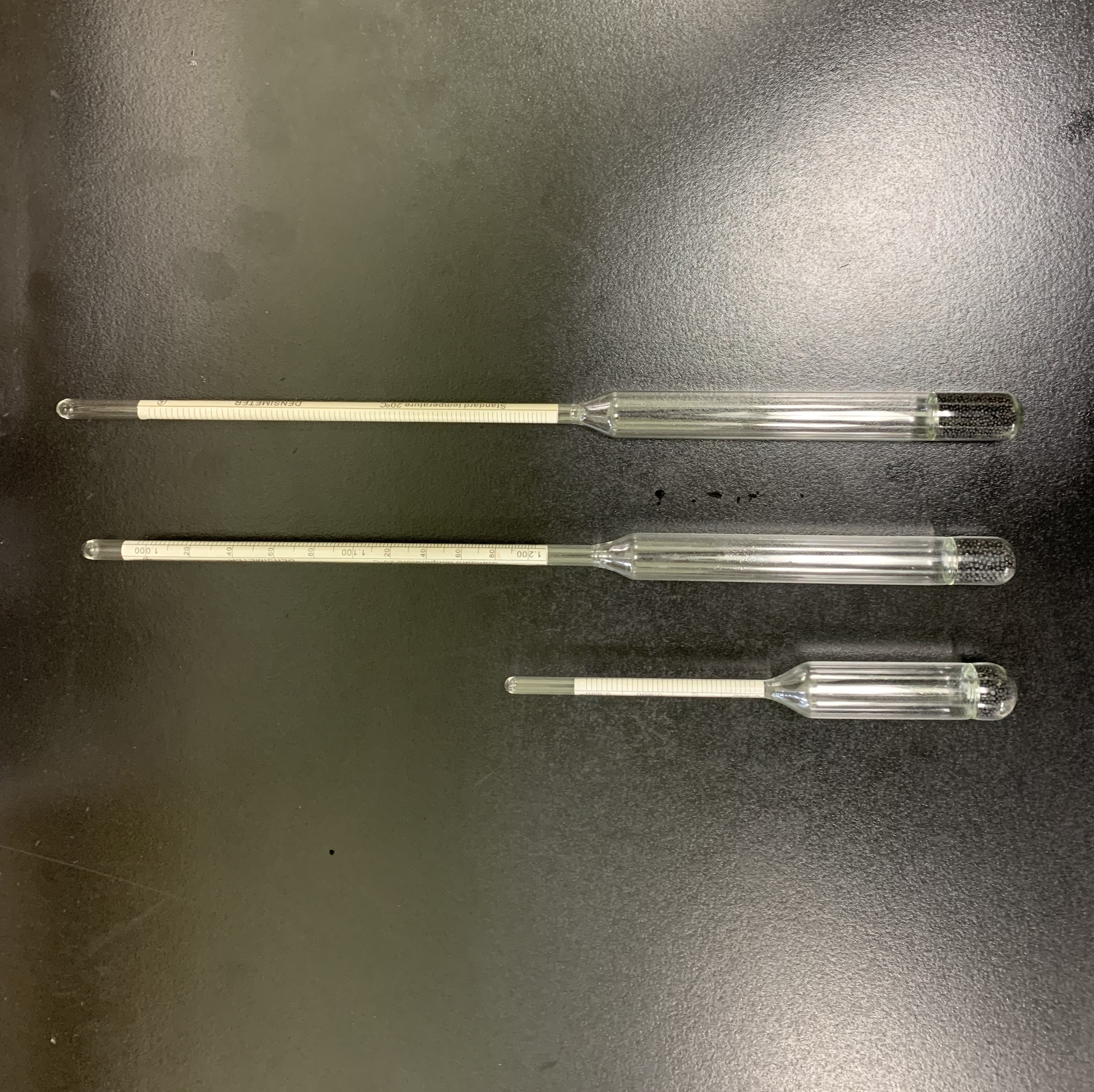

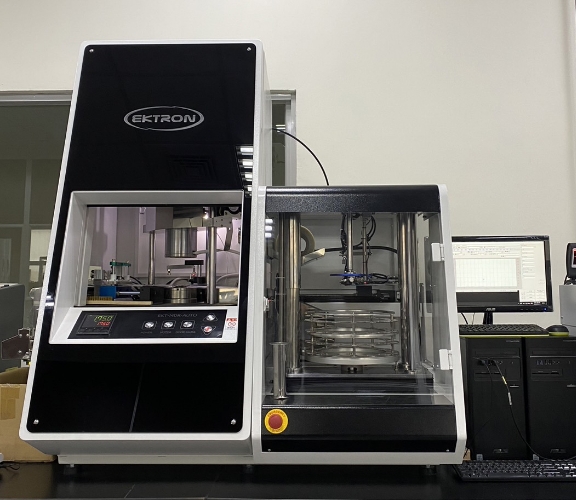

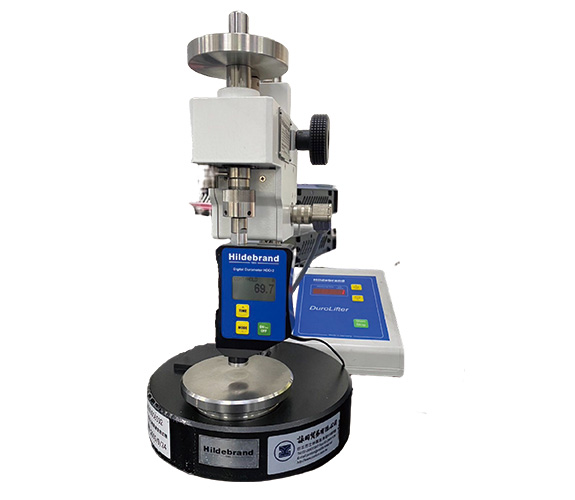

Incoming Inspection Device

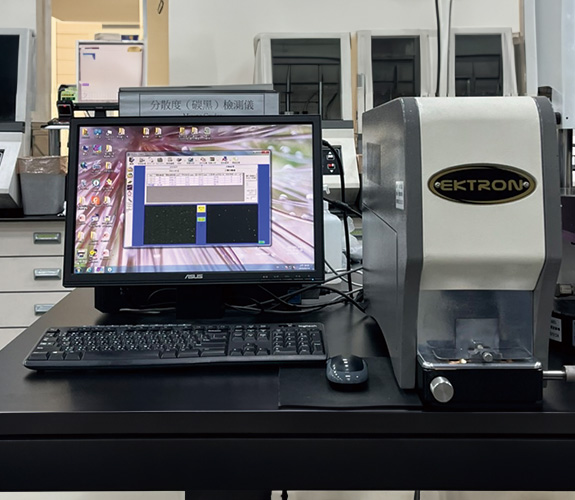

Outgoing Inspection Device

Want to learn more about smart production

We focus on manufacturing and proactively make investment in the most advanced R&D equipment and production equipment to meet customer needs and achieve planned goals. We have implemented a comprehensive production process and used electronic labels throughout the process from receipt of raw materials to final shipment of goods to ensure strict control and lot number records.